Closed Circuit Axial Piston Pump - Medium and High Pressure

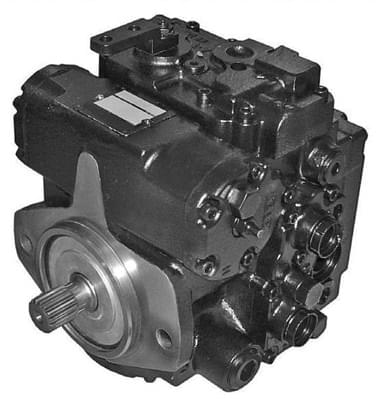

H1 Series axial piston pumps (high pressure)

With the development of H1 pumps / engines, Danfoss Power Solutions responded to the trend towards electro-hydraulically driven mobile machines with greater functionality and higher power consumption.

Higher speeds are required, lower input speeds and reducing life cycle costs. H1 is not only these requirements, but also allows for simpler, more compact designs with servo-controlled hydrostatic pumps, which can be used for increasingly complex functions . H1 is a completely new series that will be used worldwide for applications in the middle and upper performance range. The series consists of axial piston pumps for closed circuits. Fixed displacement axial piston motors.

Axial piston pumps , PLUS + 1 - compatible control software and hardware. The H1 series includes 30 power levels and/or configurations.

Quality and reliability as a design maxim:

- Uniform design concept.

- Reduced number of parts.

- Small number of control options.

- Reduced number of parts for EDC (Electronic Displacement Control).

Advantages of integration and installation:

- Optimized motor length.

- Only a clean side.

- Better ratio of peak performance and installation size.

- Integrated control function.

Standardized connection interface.

- Bigger functionality through PLUS 1.

Optimized for electrical controls.

- An electric displacement pumps for all models.

- Integrated electronic automotive control.

- Premium EDC and PLUS 1 - compatibility.

- SIL 2, Automotive Electronic Control (AC).

- 4 electrical control options (EDC, NFPE, electronic AC or FNR).

Advanced functionality:

- Integrated Automotive pumps and automotive engine control functions.

- Override of the adjustment.

- Integrated sensors optional (pressure, angle, speed).

- Electronically operated pressure limiter optional.

- PLUS 1-compatible.

More overall efficiency.

- Optimized filling pump.

- Minimum control losses.

- Improved equipment.

- Lower control pressure.

Series 90 Axial Piston Pumps (high pressure)

Adjustable Series 90 pumps are compact units with high power density. All models utilize the parallel axial piston principle, together with an adjustable tilt plate, with the displacement of the pump is controlled. By reversing the angle of the tilt plate, the oil flow from the pump is reversed and thus the direction of rotation of the motor.

The pumps of the series 90 are equipped with an integrated charge pump, which serves for replenishing of the system and for cooling of the oil flow, it also provides control oil available. They also include a number of Sly for the inclusion of additional hydraulic pumps for use in complementary hydraulic systems. To adapt to the respective control system, various adjustments are available (mechanical, hydraulic, electric) .

The Series 90 motors work by the parallel axial piston principle together with a fixed or adjustable tilt plate. Entry and exit is made by one of the terminals; bidirectional. Alternatively, a cycle purge is offered, which also provides a cooling function in addition to the purification of the oil in the working group.

- Series 90 - progressive technology of today.

- Adjustable pump in seven sizes.

- Constant engines in five sizes.

- Adjusting Motors

- SAE and slide-in mounting configurations.

- Efficient axial piston design.

- Proven reliability and performance.

- Lightweight and compact.

Series 40 Axial Piston Pumps (medium pressure)

These Axialkolbenkonstruktionen with fixed or adjustable swivel wheel speeds between zero and maximum in both forward and reverse operation can be run.

They are compact units with high power density (up to 345 bar). The change of the displacement is achieved by parallel axial piston with sliding, sliding on an adjustable tilt plate.

By the pivoting of the pivoting disc in the opposite direction of the direction of flow of the volumetric flow is reversed and thus changed the running direction of the pump.

The pumps M25, M35 and M44 are working with a direct manual displacement control. The pump for size M46 works with electrical, hydraulic displacement control or 3-point displacement control. The pumps M35, M44 and M46 are equipped with an integrated charge pump , the pump for size M25 is designed for use with external pressure supply.

- 4 sizes of Axial Piston Pumps.

- 4 sizes of Axial Piston Pumps with tandem connections.

- Adjustment and controls program - Designed for advanced propulsion systems.

- High reliability through intensive field testing.

- Optimal usability through standardized fittings and modular design.

- Compact.

- Low noise.

- Worldwide sales and service.

Series 42 Axial Piston Pumps (medium pressure)

Adjustable Series 90 pumps are compact units with high power density. All models utilize the parallel axial piston principle, together with an adjustable tilt plate, with the displacement of the pump is controlled. By reversing the angle of the tilt plate, the oil flow from the pump is reversed and thus the direction of rotation of the motor.

- Pressure up to 415 bars, drive speed max . 3750min -1 ( on size different)

- Multiple adjustment : electro- proportional, mechanical.

Sizes:

- 28cm³/U, 42cm³/U, 51cm³/U (Single and multiple execution)